Audio Tone Control

Thore Lencer, Prof. Dr.-Ing. Ralf Sommer

GaSt Praxisseminar WS 25/26

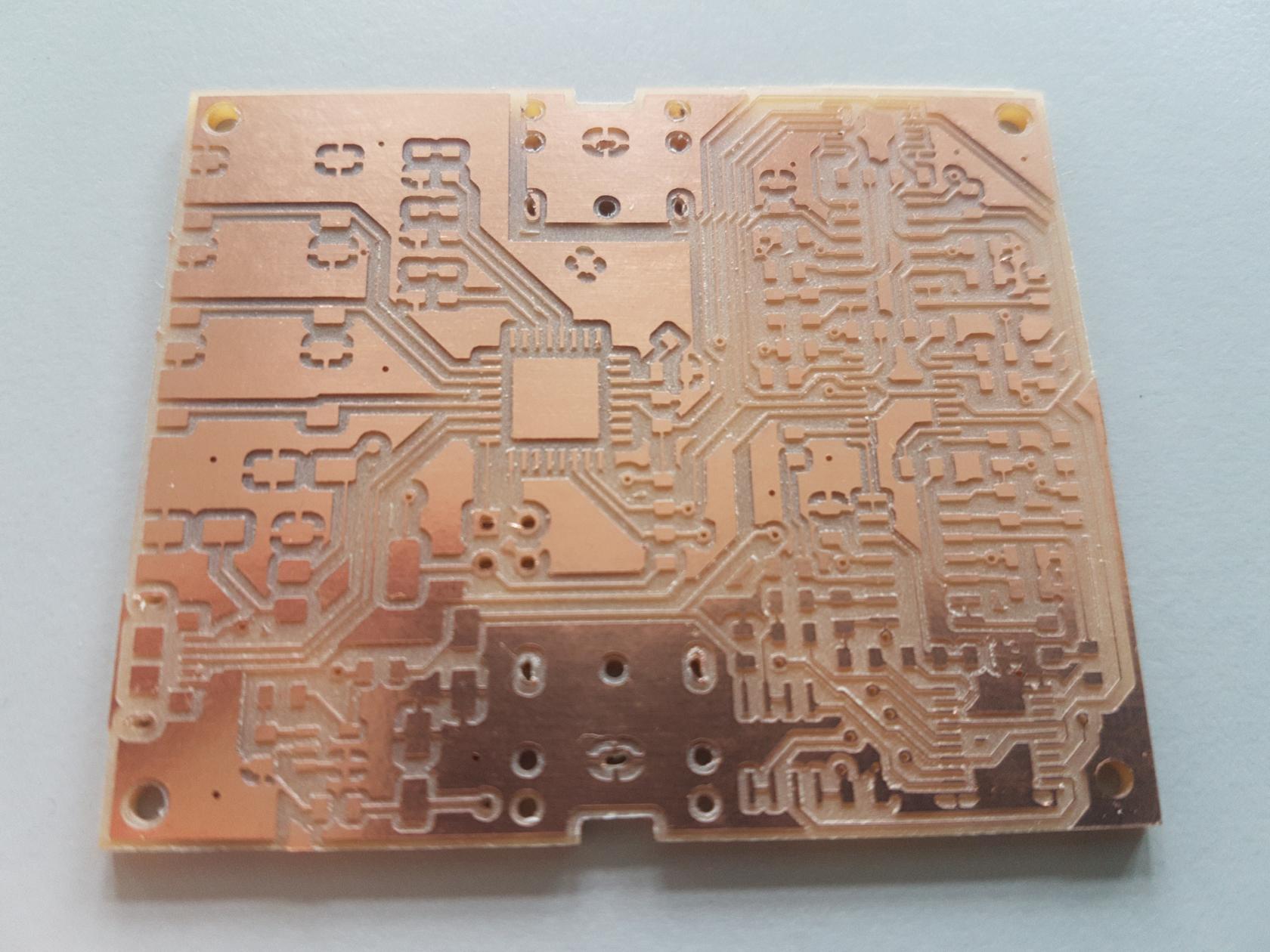

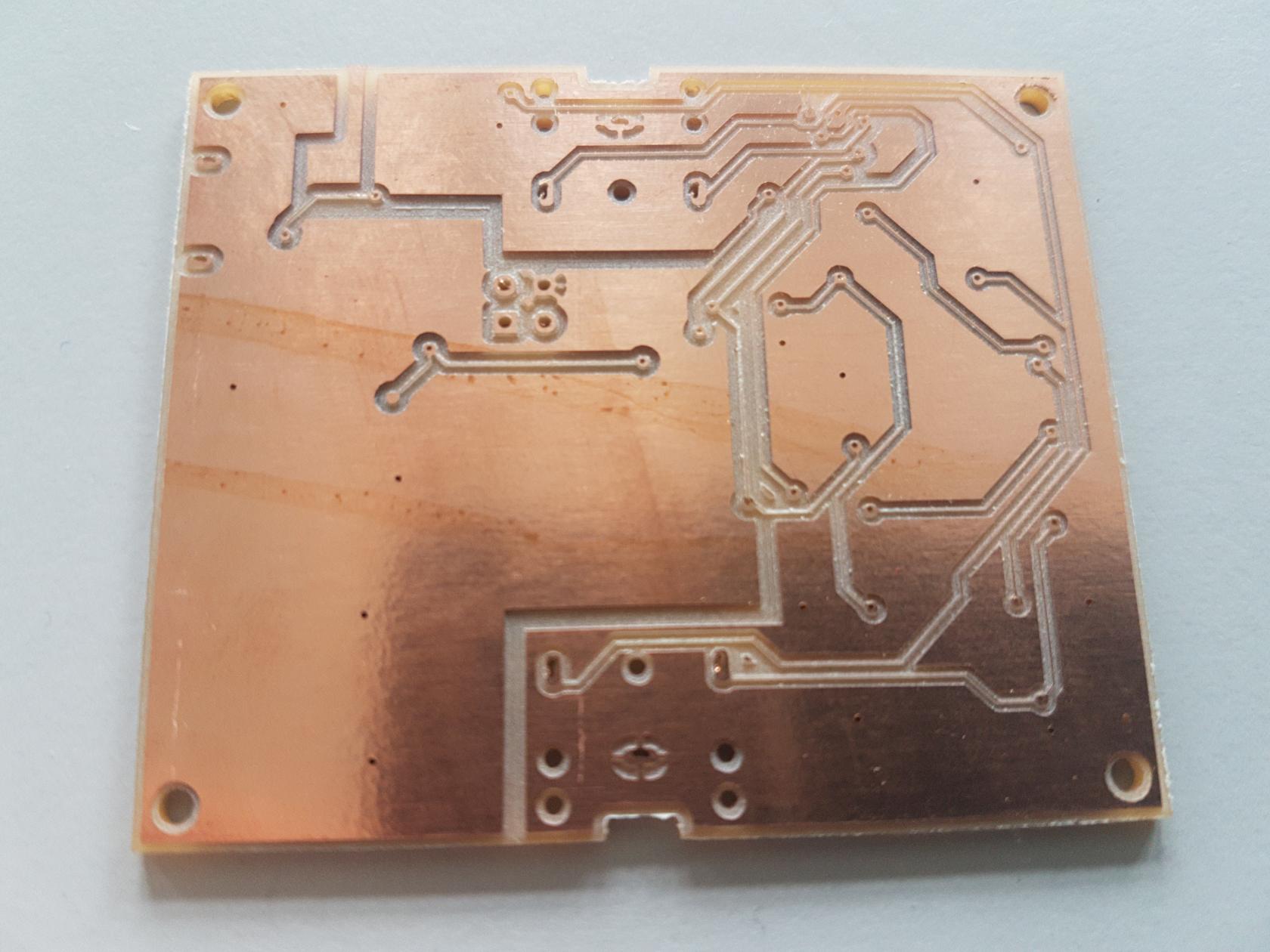

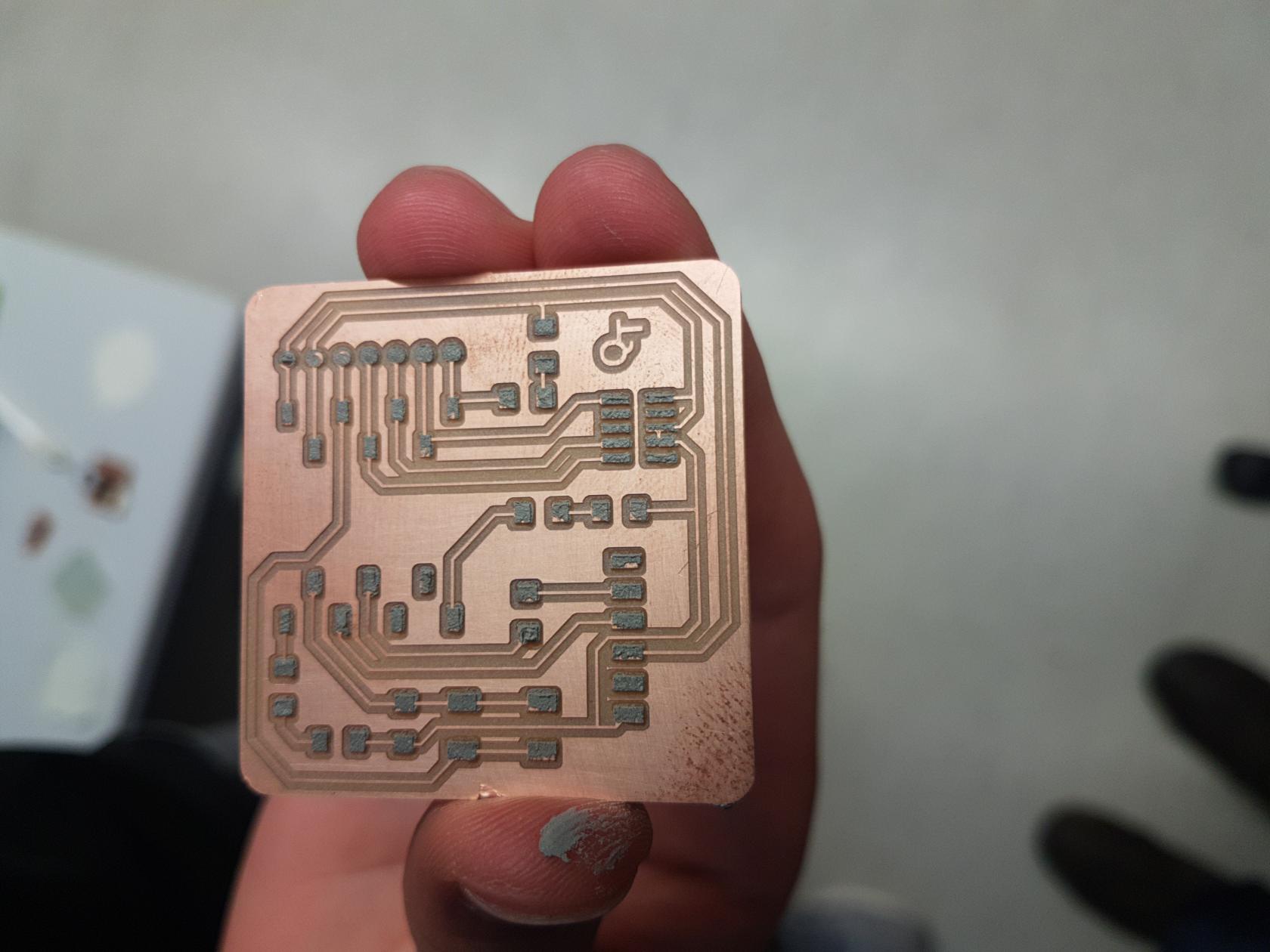

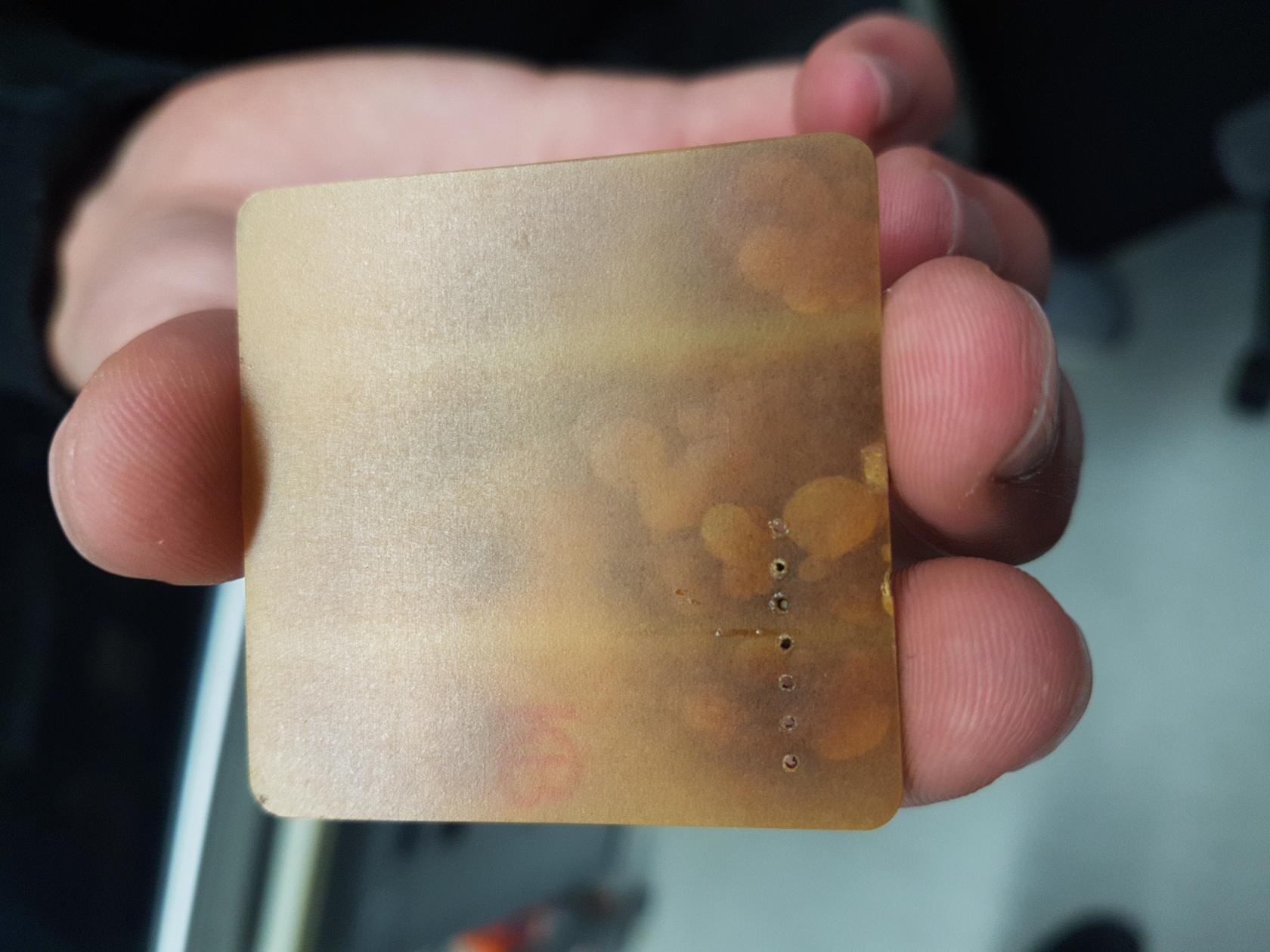

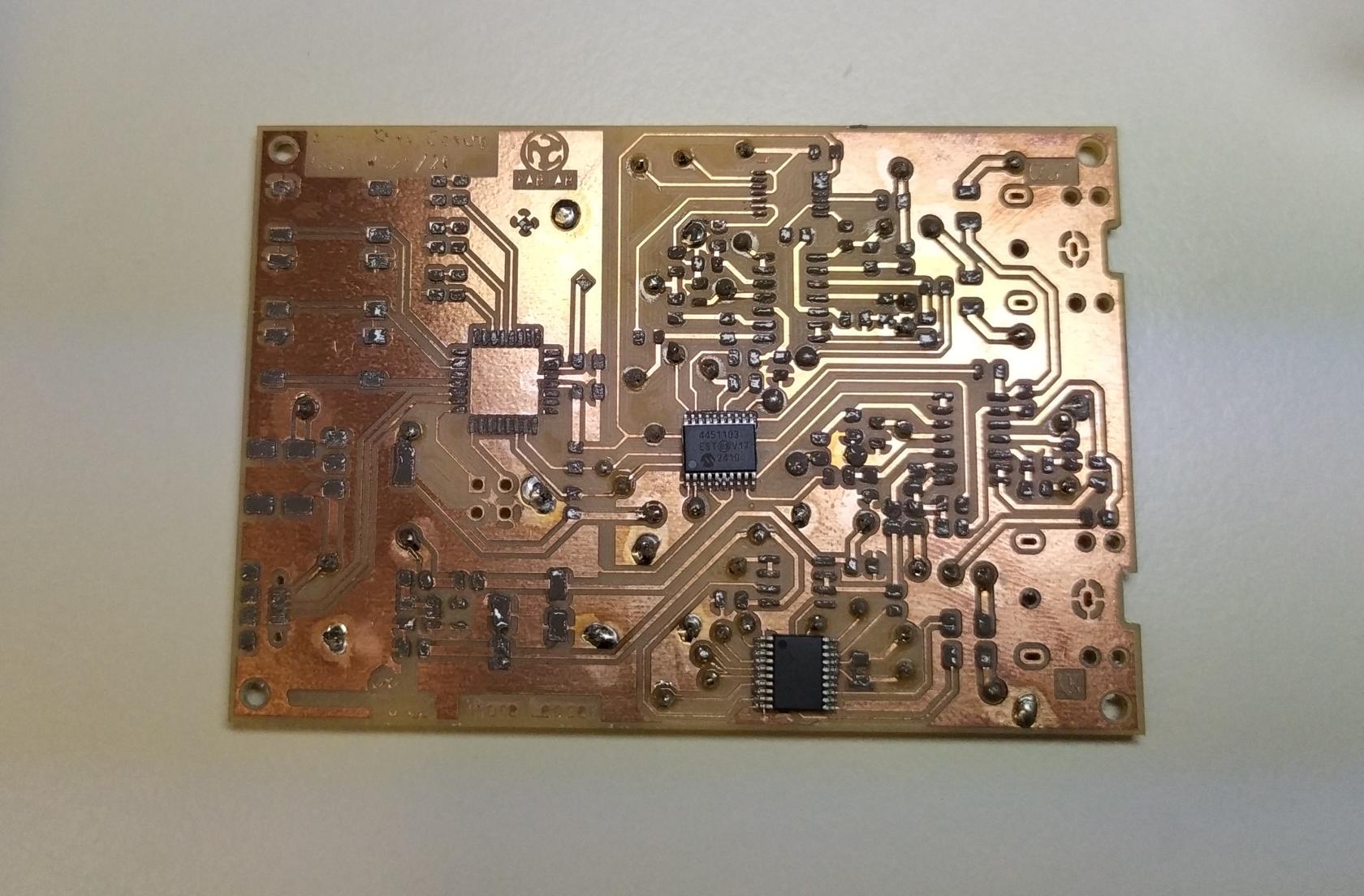

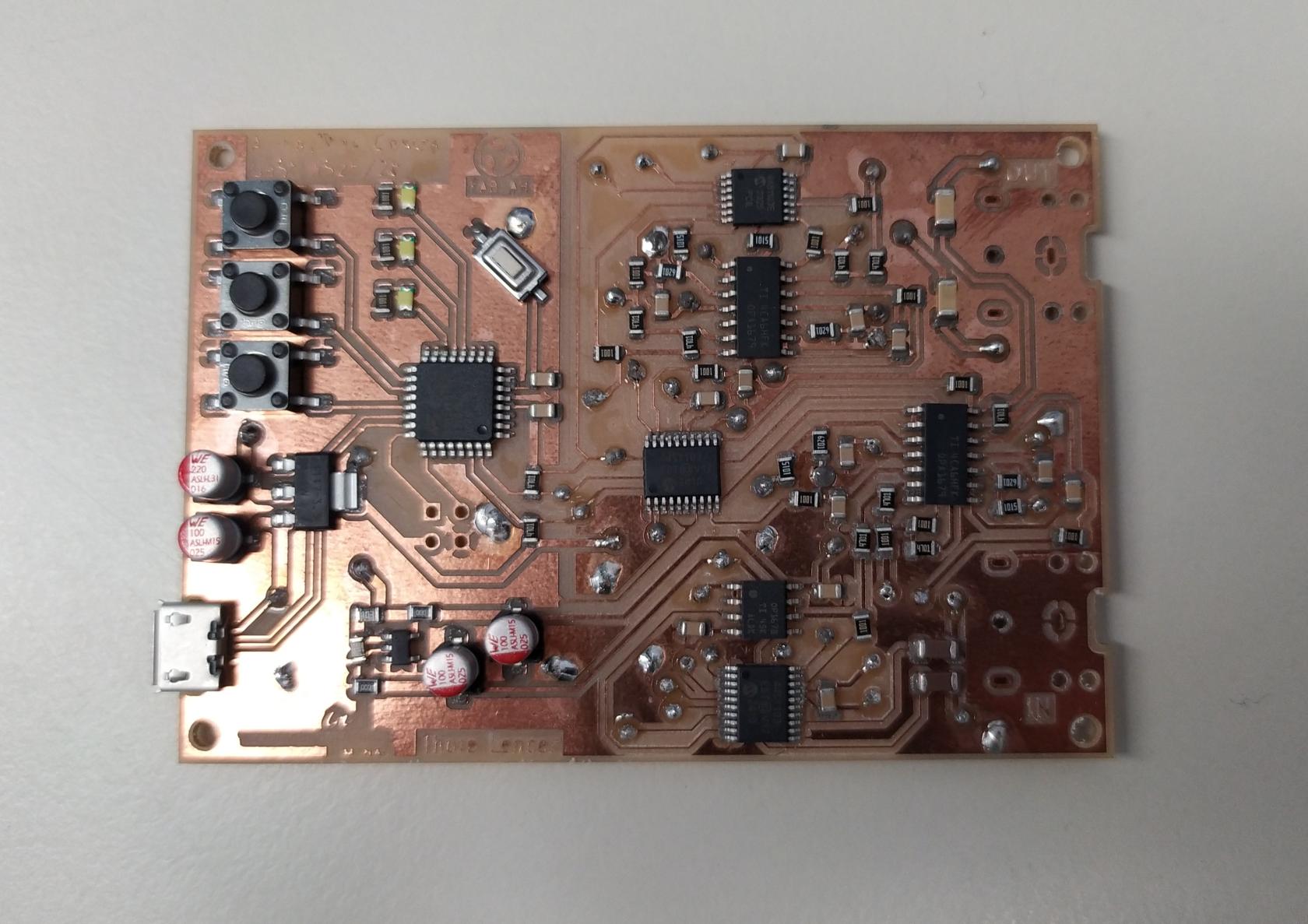

Probably our most complex double sided PCB so far.

Size ~60x50mm

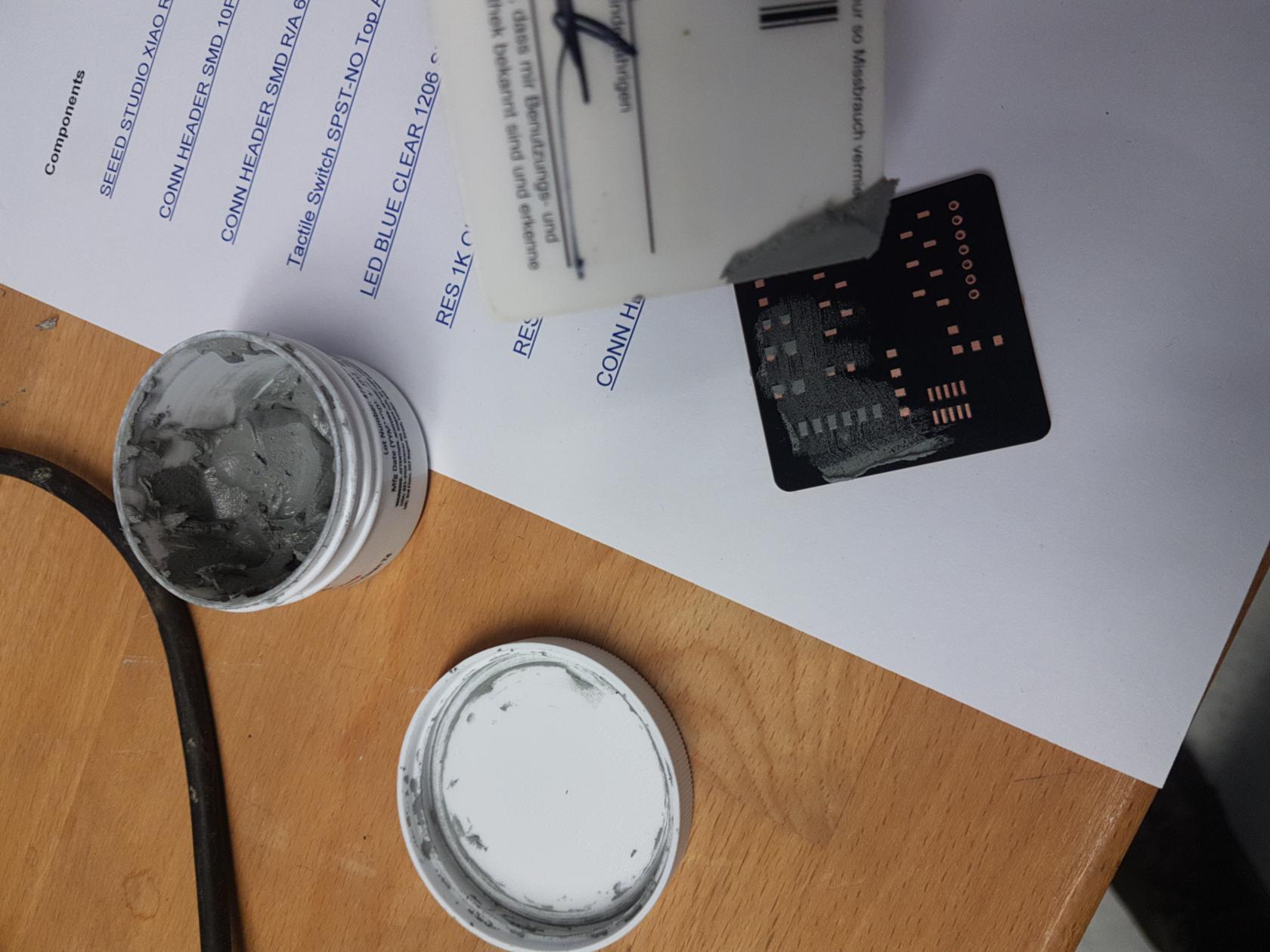

We are working on soldering this board with our Reflow-oven.

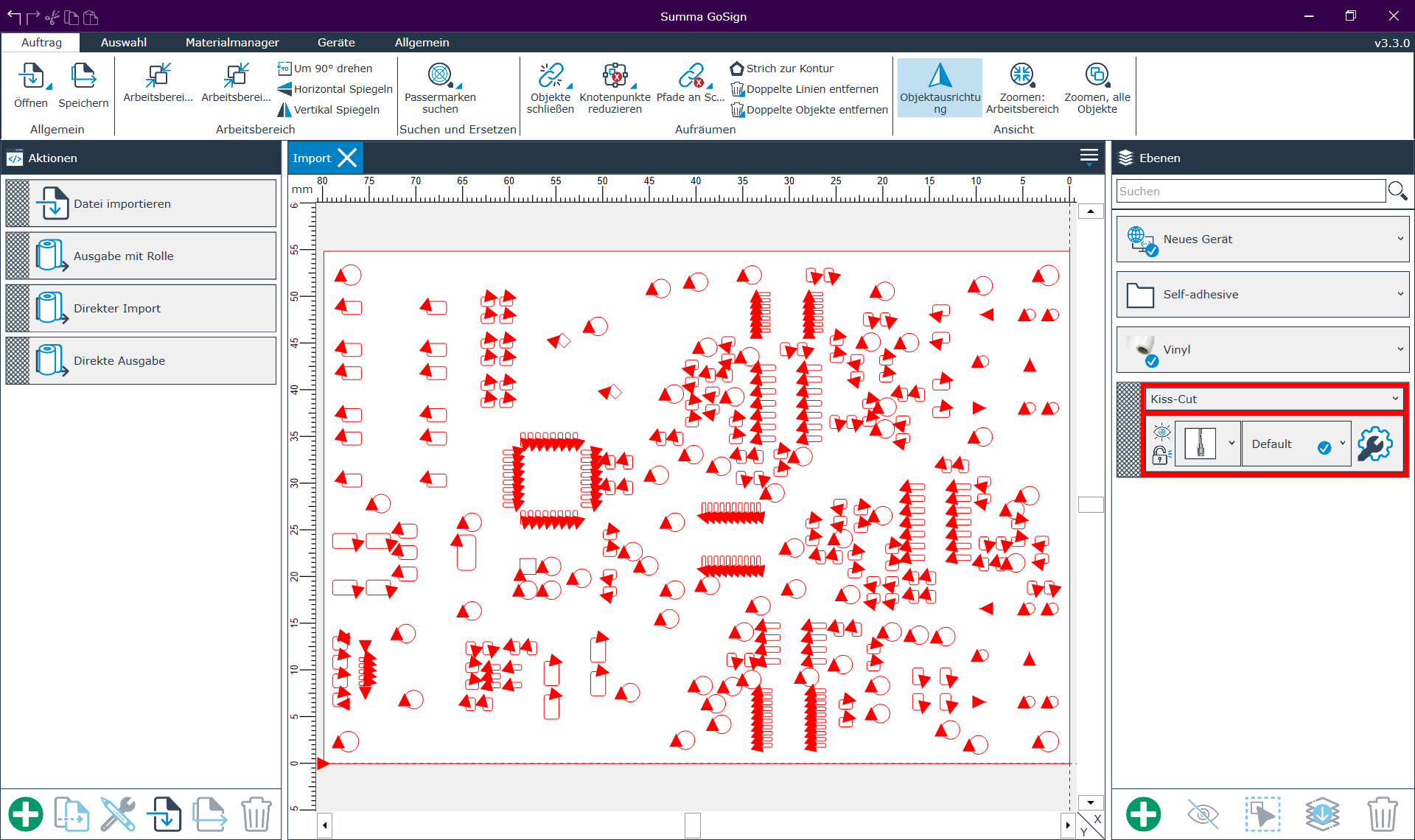

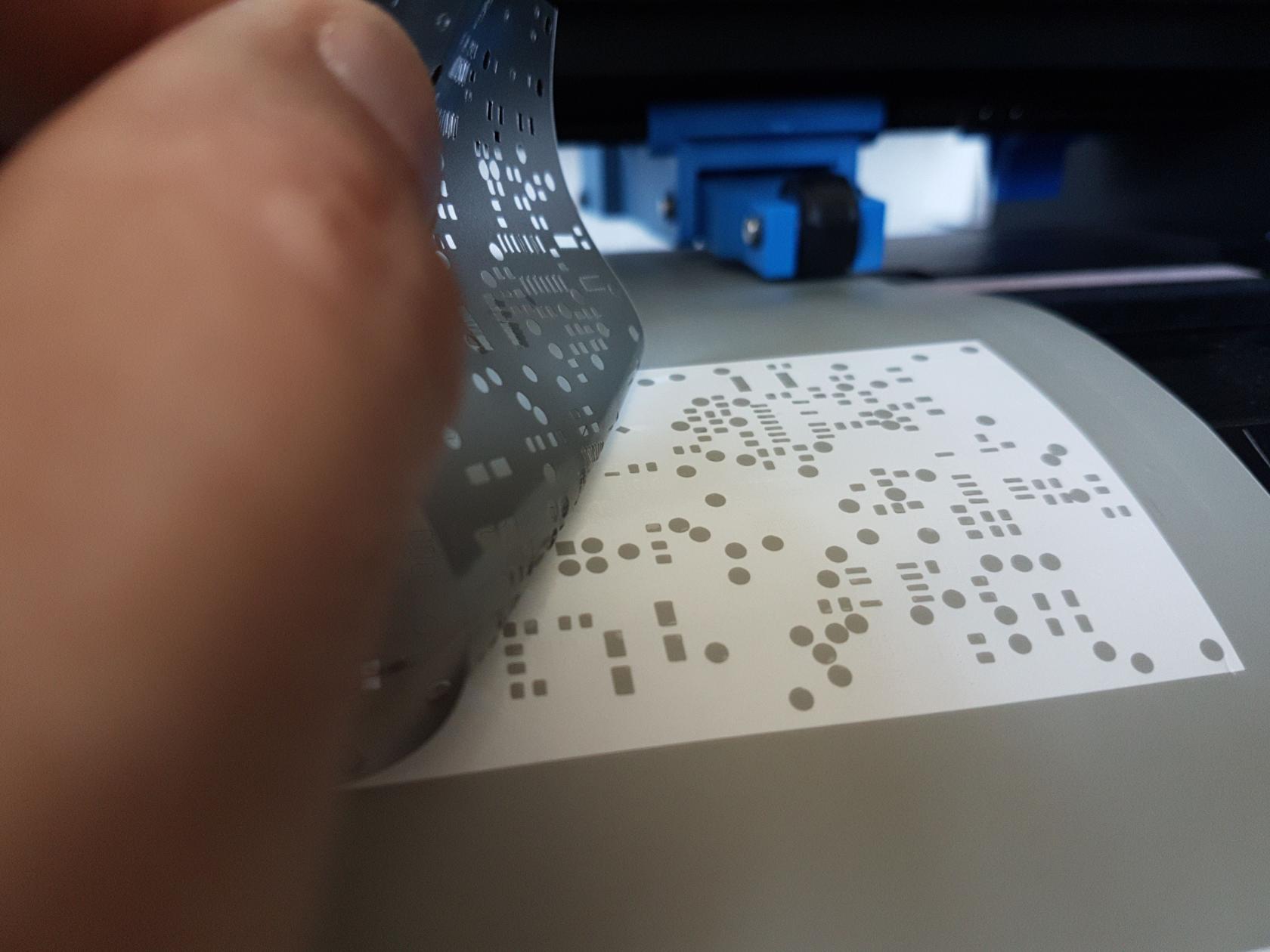

We want to try making the solder-paste stencil with our vinyl-cutter:

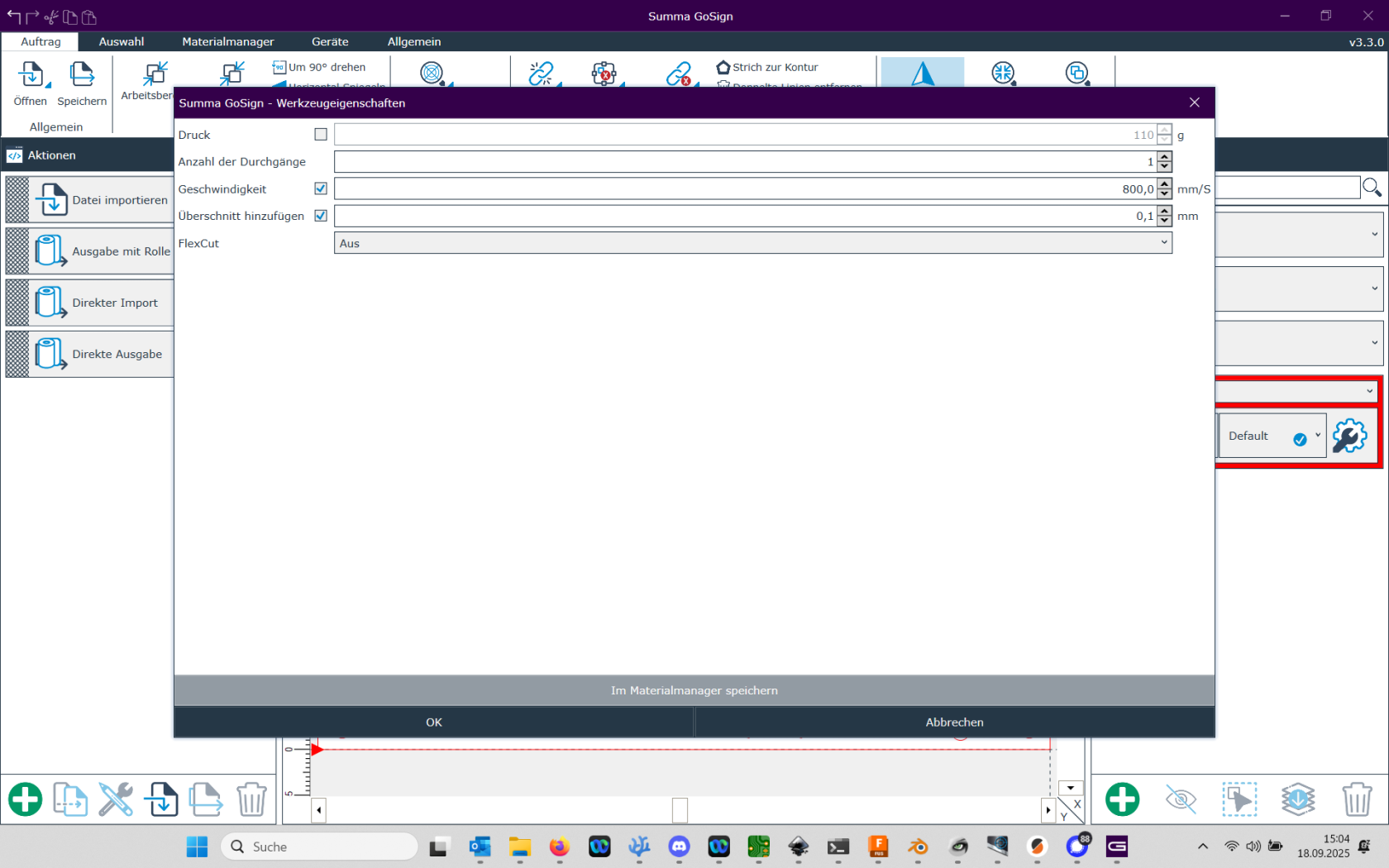

Above is a screenshot from GoSign, our software for the Summa S3 T75.

This is an attempt with a speed of 10mm/s instead of 800mm/s:

The first stencil looks very promising!

Reflow soldering

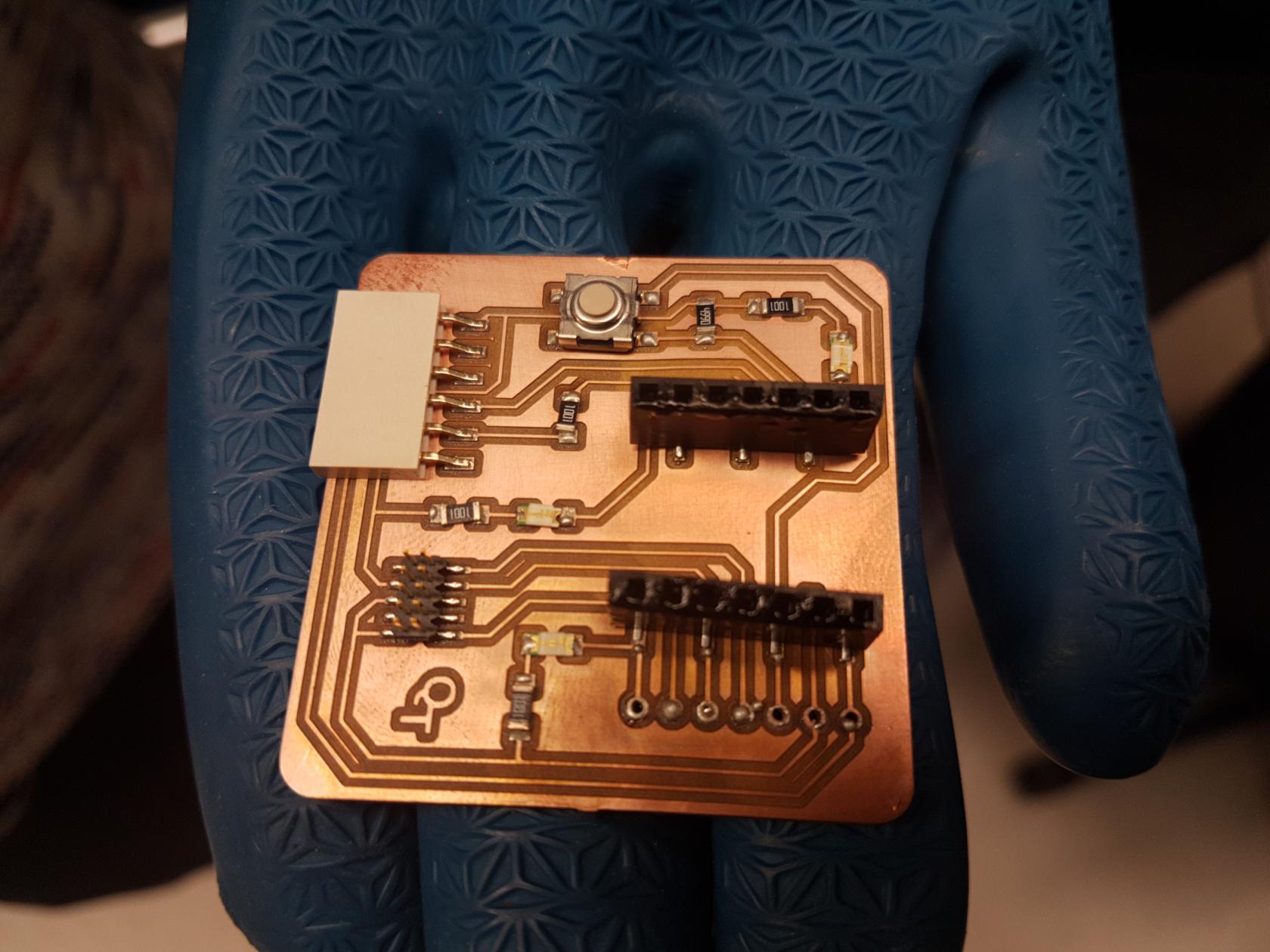

Placing all components:

Good settings for perfect TSSOP package and 0,4mm traces copper milling: 0.2mm v bit but insert 0.25mm in modsproject with 0.25 stepover and 4 offsets

Solder mask removal: Solder mask removal bit; Z calibration with multimeter; then step up by 0,12mm and step down slowly if needed; cure UV mask for 5min first, then mill, then final-cure; cut speed 5mm/s; plunge speed 2mm/s, spindle 6000rpm

Drill after solder mask application! Elsewise solder mask gets into the holes and copper can be destroyed when there are thin pad rings

No comments to display

No comments to display