Galvanizing

Notes from Jakob (may need refinement)

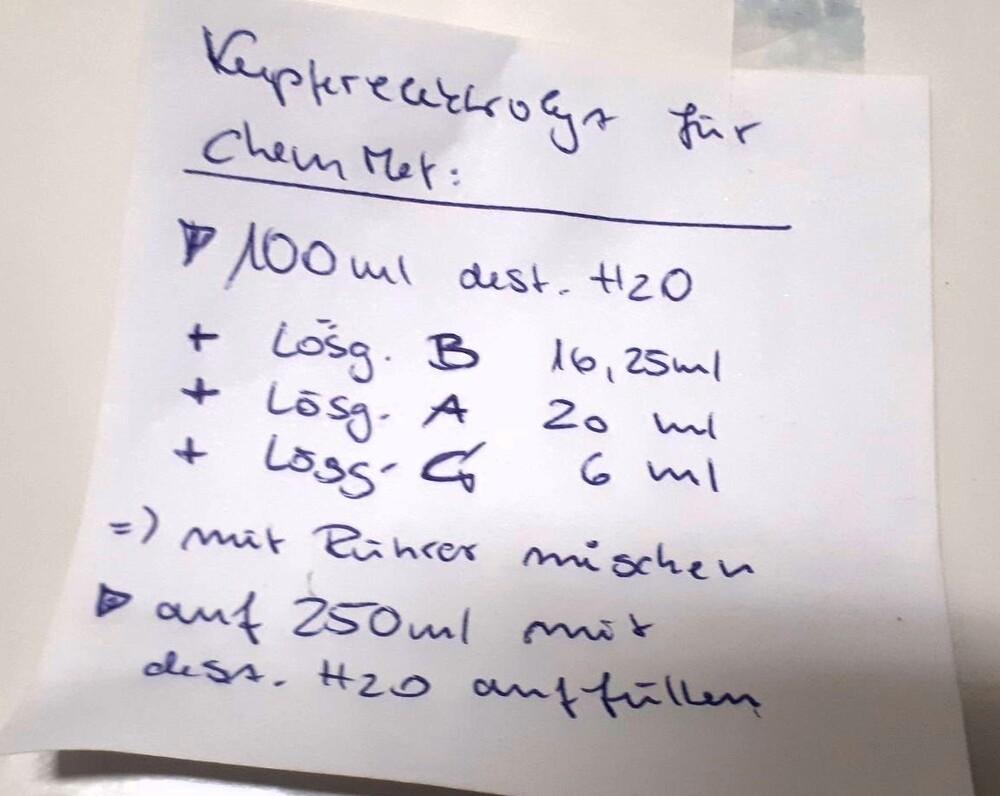

- copper sulphate

- solution a (copper sulphate)

- solution b

- solution c: caustic soda and formaldehyde

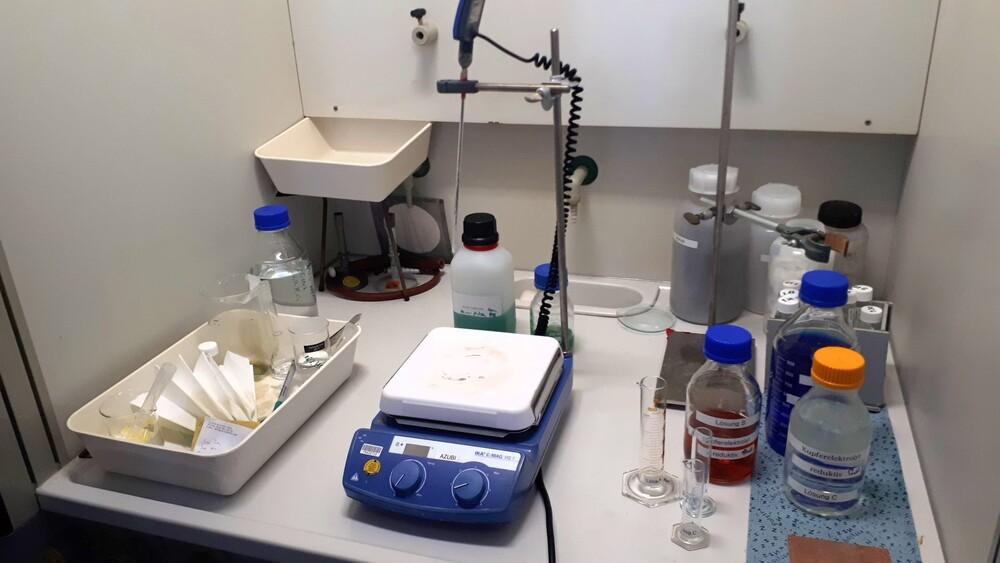

heating plate

-

medium to be electroplated

-

monodistilled (once distilled) water

-

fill with water

-

heating plate underneath (with magnetic stirrer)

-

put thermometer (sensor) on top

-

heat to 50 degrees

-

add ingredients according to recipe in order.

-

todo: translate recipe

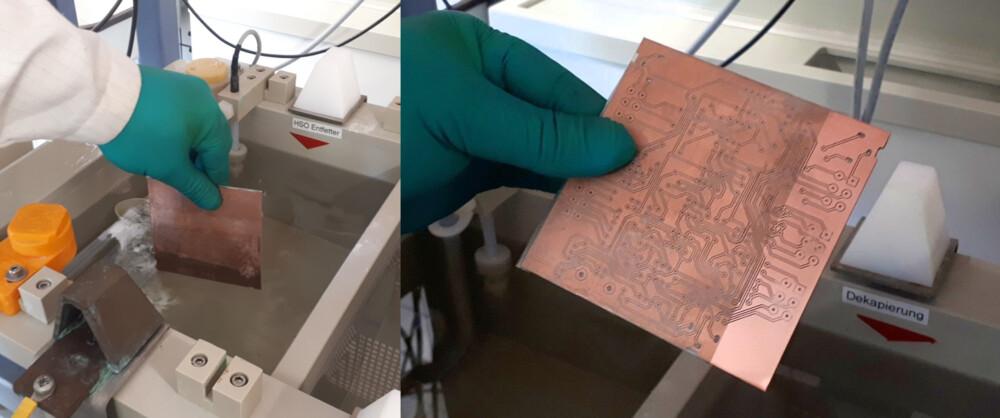

pre-treatment of plate

-

hso degreaser

-

caustic soda and disodium tasylate plus something like fit

- degrease

-

this forms very small oxide layers. we want to rinse these off

-

rinse (with water)

-

put the piece in solution

-

how thick should the layer be?

-

3 to 8 μm per hour

-

the bath is set to slow. why? because the bath is there to do selective coating. that means you want to coat one part and not others.

-

3d printed circuit boards can also be made with it. can be injection molded and then coated in electroplating

-

3d plastic: copper particles in plastic. expose with a laser and electroplate.

- 3d mid

-

process only works because there is a bit of copper on the surface. the copper acts as a catalyst.

if i now want to electroplate a sheet, i have to dip it in a solution beforehand so that a metal layer is deposited on it.

- the following would be possible:

- palladium, silver etc. the only question is how to get it onto the surface

- we use palladium because it's a very good catalyst. it's a very good catalyst because it can be plated with