dr4wbck

The Idea

Initialy our Idea was to build the AxiDraw but with a Capsten-Drive and in Core-XY style to not need to have a typical belt and only need a rope or fishing line (and we wanted to try out this cool new technic :D).

For this, we took big inspiration from the UrumbotXY 2.0 and first tried to imagine, how we need to align the bearings to get the desired movement.

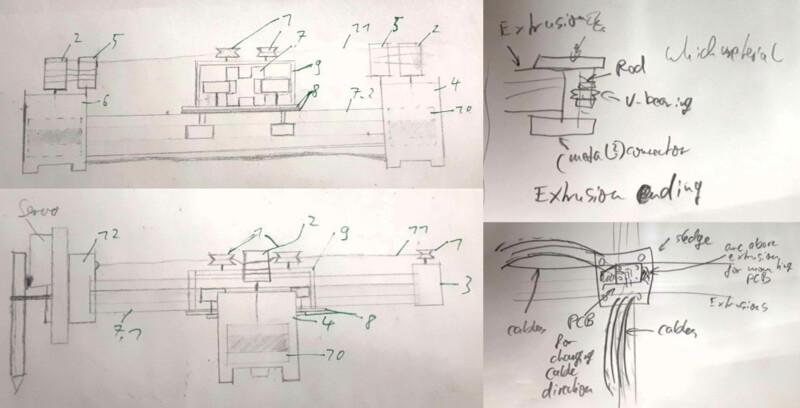

We made some initial sketches to better understand, how the machine whould look like and what parts we needed.

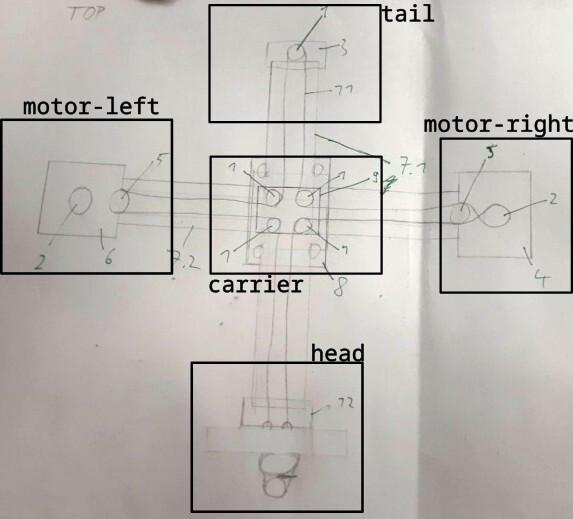

Then we seperated the machine in different parts that needed to be designed and to be done.

Also here you can see the inital concept, which was that the corner-bearings are placed on the middle carrier and the rope is fixed on the head. (and also here we planed to place the carrier bearings over the second axis)

We where a bit overwhelmed of all the tasks that needed to be done and first needed to get into managing the tasks and distribute the tasks in the team.

So we split the work into thouse sub-tasks

try out and get theRAMPSworking withPrintrundesign the different parts of the x and y machine axisdesign a head for the pen with z axisproduce and test the prototypes and needed parts

Initial Design

In the initial design, we kept the design simple so we could produce them fast and test out the mechanism.

So we build a simple motor bracket for the motor and the linear rails:

Then we produced the capston and pulley from the UrumbotXY 2.0:

An Initial head for:

Then for the carriage we had a Metall Carriage already as a part, which was very sturdy.

Here we needed to be carefull with the screws.

But the wheels for the second axis where on top of the other wheels, which we couldn't implement and Ferdi advised against it.

The tail was designed with only one wheel, which may have bin one cause for our problem.

Then we redesigned it to use both metall carriage, which was pretty sturdy. Also we used eccentric screws to tighten the rope.

Then we designed a head for initialy screw down and tighten the rope.

Also we produced a wire chain to connect the head with the board. In the end we noticed, that the chain was not that sturdy and was not that usable for our machine -.-.

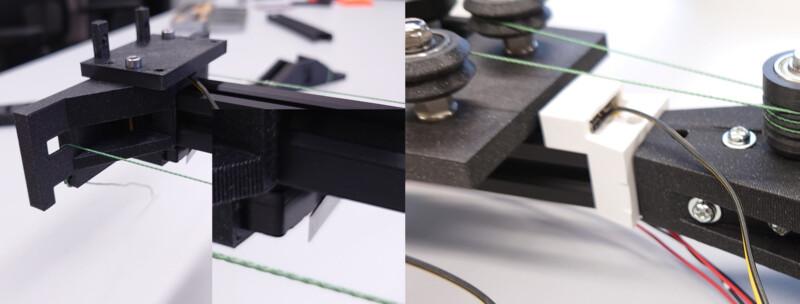

First Assembly

After designing and printing, we assambled everything...

... cut threads, screwed everything down, assambled the capston drive rope...

... and tried to operate it manually:

yay :D

And it worked nicely :P

Continuation & Redesign

When operating manually, we needed to hold it down so that it is stable, which was the first thing we improved.

First just making a little angle in the motor bracket improved it a lot but still was oscillating...

... so we created a sideway stabilisation, which then was pretty stable.

Here the head and the initial design for lifting holding and adjusting the pen.

Then we inkluded in the head and on the side an endstop for executing g-code.

And also a never produced new cariage for mounting the cable chains for the head.

LessonsSetting Learned

distributingup theworkDriversSetting up the Firmware

Getting it Running

#define BAUDRATE 250000Determine Steps per Millimeter

// Enable one of the options below for CoreXY, CoreXZ, or CoreYZ kinematics, // either inatheteamusualisorderhardor- reversed

also#definefindingCOREXYparts,//#definethatCoreXZcan//#definebeCOREYZoperated//#defineonCOREYXparallel//#defineisCOREZXnot//#definethatCOREZYeasy

/**

nothings* worksDefault outAxis asSteps expectedPer and things that can go wrong, will go wrongUnit (aslinear=steps/mm, toldrotational=steps/deg)

so* before)wewith shouldM92

have* partitionedX, ourY, timeZ more[, efficiently,I then[, weJ whould{, haveK...]]], hadE0 a[, goodE1[, workingE2...]]

product*/

on#define timeDEFAULT_AXIS_STEPS_PER_UNIT and{ not102, spend102, time400, on500 little,}

not