CNC mill JarBeRi

CNC Mill by Jarni, Benedik, Richard

Workflow:

Links:

https://cloud.tu-ilmenau.de/apps/files/files/104312242?dir=/Benutzer/CNC%20JarBeRi

3D modeling:

- Everyone is working on their subassemblies.

- Work in private directories

- Upload versions to the shared folder

Design decisions:

General

Standart PCB Sizes:

- metric: 150mm*100mm

- imperial: 127,38mm*102mm (5inch * 4inch)

Material Goals:

- PCB milling very precise

- 0,4mm traces

- Engrave stone

- soft limestone

Work Table (fixed)

- 160mm*120mm

- 15mm? height

Outer Dimensions: (might change based on final design)

- 350mm width

- 300mm depth

- ? height

Assembly Groups:

Mechanical:

Y-Axis: (Jarni)

- leadscrew: trapezoidal thread T8

- two T8 nuts countered for minimal backlash

- new stepper + axle coupling

- preferred: prusa stepper axle assembly

- bushing for trapezoidal axle

- guiding rods

- 8mm

- linear bearings

- sled

- 3d printed part, maybe milled aluminium

- support structure for lower bed

- interface plate

- holes for T-Slot nuts

- friction fit for guiding rods

X-Axis: (Benedikt)

- leadscrew: trapezoidal thread T8

- two T8 nuts countered for minimal backlash

- new stepper + axle coupling

- preferred: prusa stepper axle assembly

- bushing for trapezoidal axle

- guiding rods

- 8mm

- linear bearings

- sled

- 3d printed part

- connected to z-axis

- interface plate

- holes for T-Slot nuts

- friction fit for guiding rods

Z-Axis:

- manual adjustment with screws

- flexure mechanism

Machine Bed (work table):

- upper bed: (waste board)

- HDF/MDF

- screw holes for fixturing?

- lower bed: steel or aluminium

- connect upper bed and lower bed with screws

Spindle and Spindle Mount:

- which BLDC motor?

- BLDC motor

- treaded inserts for the mount

- spindle collet

- high strength ABS 3d print

- mill out of aluminium

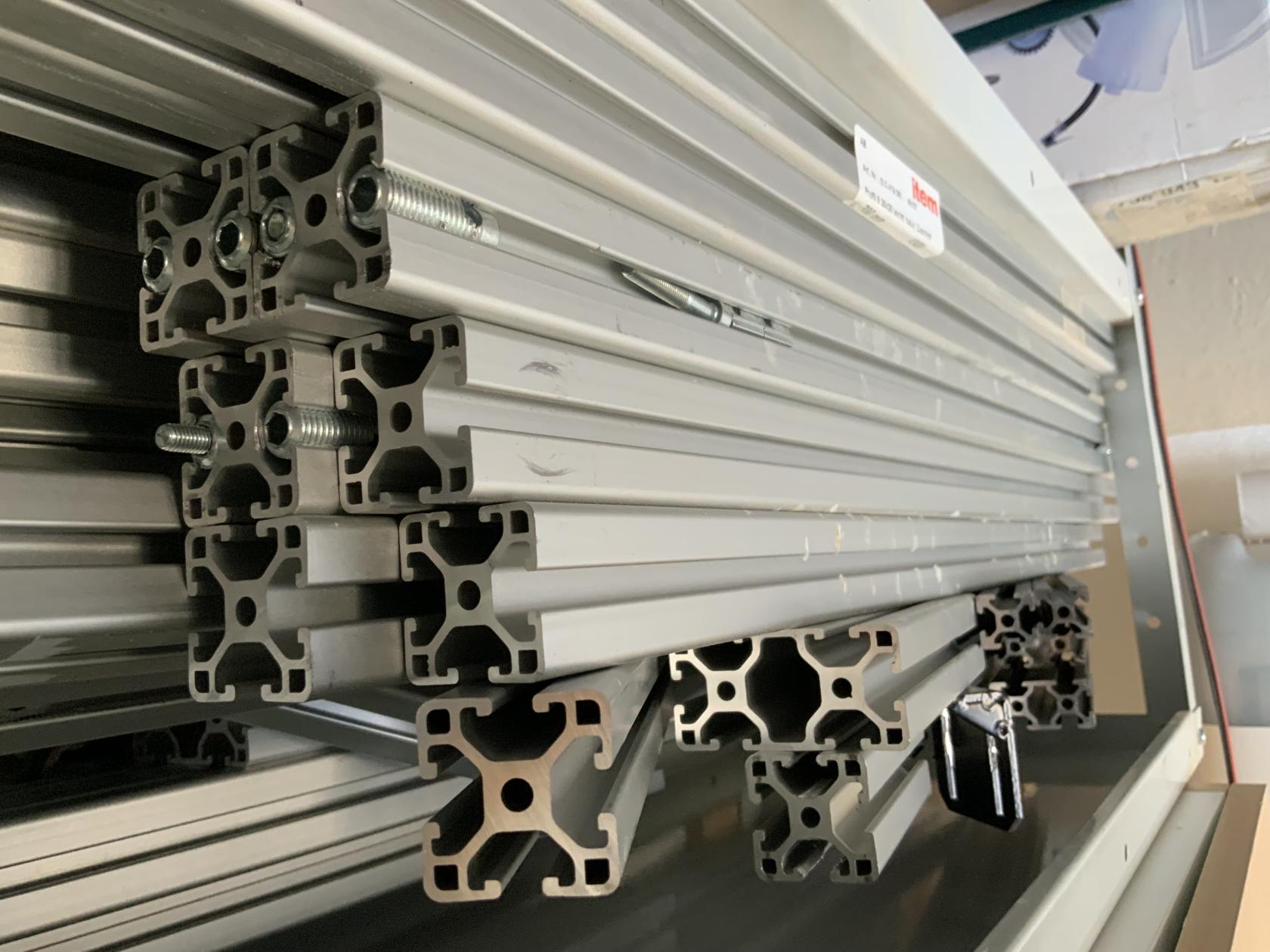

Frame:

- use existing: ITEM Profile 6 30mmx30mm (0.0.419.06)

- vertical: 60*30 extrusion

- horizontal: 30*30 extrusion

- additional support by steel wires for structural rigidity

- T-Nuts

Electric:

- human interface

- housing

- display

powersupplypower- lab bench powersupply

- cables

- Motors

- Stepper Motor

- plugs

- mechanical coupling

- Spindle Motor

- BLDC

- BLDC driver board

- Stepper Motor

- Endstops

- microswitches

Software:

- search for:

- Arduino mega software

- motor drivers libraries

- uns Fusion360 for 3D model -> nc code

Project Progress / Docu:

First Idea to Sketch:

On Thursday, the day after the Mechanical Design and Machine Building lecture we decided to form groups in our local lab. It wasn't easy to form a group in the first place but after longer discussion we formed a group of three: Jarni, Benedikt and Richard.

We wanted to build a use full tool for our lab and get some redundancy for our existing CNC the Carvera Makera. Machines often have issues or have downtime due to maintenance thats why it is use full to have a backup if something goes wrong with the Carvera mill. For us building a X-Y-Z computer controlled coordinate system was a completely new topic, what made this project exiting in the first place. We took our existing machines in the lab as a reference and did some research online about homemade CNC's. We checked the following:

- Carvera Makera

- Prusa MK4s printers

- Pico V2 milling machine

- Ferdis existing knowledge on CNC's

Ra

What ist RapRep?

RepRap is humanity's first general-purpose self-replicating manufacturing machine.

RepRap is openSource soft- and hardware framework that has many derivitives and versions. For our project we used the standart RAMPS 1.4 board and a Arduino Mega.

RAMPS board

We used the offical documentation of the RapRep

Functions we need:

- Endstops

Functions we do not need:

- Heatbed controll

- Hotend controll

Endstops

official Wiki RepRap - Endstops

RAMPS 1.4 offers no pull-up circuits, current limiting resistors or other protections.

Wiring improperly an endstop that uses 5V may damage an IO port on the ATmega 2560 or the Arduino itself, this is a particular issue with clones of the Arduino ATmega2560.

- put pull up and pull down resistors close to the board

In firmwares a setting is available to enable or disable built-in pull-ups, for example in Marlin you have the ENDSTOPPULLUPS constant in configuration.h, this option is enabled by default.

- different Endstop versions are available

- usually PCB mounted

Motors are a common source of noise. Keep endstop wiring away from motors or use strategies like twisted cables or or used screened cables to reduce the noise.

Firmware

- use Marlin Firmware

idea list:

component list: mechanical structural: - alu extrusion 20*20 moving: - 2x 8mm leadscrews with brass nuts - 4x 8mm guide rails - electrical: mechatronic: manufacturing methods:

- milling parts

Links:

-

https://marlinfw.org/

design decicions: